Concrete Driveways, Walkways, Stoops, and Patios

When it comes to upgrading your home’s exterior, concrete driveways shine as a top-notch option, offering both aesthetic appeal and a solid return on investment. By ensuring proper installation and regular upkeep, a concrete driveway can last well beyond 20 years, requiring minimal maintenance expenses to keep it in top shape. Moreover, the option to add color and stamping to your concrete allows you to create a truly customized driveway, tailored to your specific taste and preferences.

Pros of concrete

- Properly installed concrete offers an extended service life and typically does not entail the need for frequent maintenance.

- Has a long lifespan.

- Despite being low maintenance, concrete driveways may benefit from resealing every 3-5 years to ensure their longevity, accounting for care and the extent of daily usage.

- Better in warm climates as it does not soften.

- Can be colored and scored.

CONCRETE PAVING SERVICES

CONCRETE EXTENSIONS & WIDENING

Concrete Driveways & Garage Floors

When extending a concrete driveway according to usual standards, it involves removing and disposing of 9 inches of dirt, incorporating 4 inches of CA-6 stone, wire mesh reinforcement, and finally pouring a 5-inch layer of concrete.

For durable and dependable Concrete Paving in Antioch, Illinois, it is best practice to construct driveways with a minimum combination of 4 inches of CA-6 stone, wire or fiber mesh reinforcement, and a top layer of 5 inches of concrete.

With a parallel profile to the driveway, the Concrete Garage Floor creates a seamless transition in terms of design and aesthetics. Additionally, the utilization of decorative concrete coatings provides an avenue to enhance its allure and infuse it with character.

At the interface where the new concrete meets the old concrete, expansion joints are deliberately installed, for instance, where the recently constructed driveway intersects with the pre-existing garage base.

Selecting a six bag mix of Concrete with a 4,000 PSI rating is crucial to ensure that your Concrete Paving project in Antioch, Illinois achieves the maximum strength required.

Concrete Walkways

Walkways in most regions have a standard width of 3 feet, but the front walkway is often wider. During the installation process, a base layer of 4 inches of CA-6 stone is laid down, followed by a 4-inch layer of concrete for the walkway.

For private walkways, the ideal approach is to create a solid structure by using 4 inches of CA-6 stone as the base and pouring a 4-inch layer of concrete on top.

When it comes to city walkways, it is recommended to create a strong and durable structure by using a 4-inch base layer of CA-6 stone and pouring a 5-inch layer of concrete on top.

When considering the City Approach, the thickness of this area, which lies between the city walk and the road, can differ from village to village, commonly requiring 6 inches or more of concrete.

Concrete Stoops and Steps

Creating a comfortable and safe step down without any trip hazards can be achieved by extending and widening concrete stoops and steps as needed. Concrete Paving in Antioch, Illinois is carried out with meticulous attention to detail and adherence to standards. By utilizing a 7-inch depth for steps, in accordance with industry best practices, and strictly complying with village codes and typical engineer specifications, we guarantee precise and accurate results.

Enhancing the look of concrete stoops can be achieved by overlaying or “capping” them with pavers or natural stone, offering a more classy and refined visual appeal. It is a common design choice to intentionally enhance the front entrance by using pavers or stone, such as bluestone or flagstones, while pouring the rest of the space with concrete.

Choosing to level the concrete stoop with mortar or screenings and overlaying it with brick pavers or natural stone offers a cost-saving option compared to the expense of complete stoop replacement.

Concrete Patios

When it comes to Concrete Paving in Antioch, Illinois, our expertise in installing concrete patios has made it one of our most sought-after and highly regarded services. We recognize that every property has its own unique style, and that’s why we provide a wide range of patterns, colors, and stamps to ensure your patio showcases the individuality and character of your property.

If your patio feels too small, the option to extend it with new concrete is available. However, to maintain a unified and visually pleasing result, it is generally preferred to redo the existing patio.

CONCRETE PAVING PROCESS

STEP 1.

DEMO, BASE & FRAME

Our dedicated crew will commence by removing the current surface of your driveway or patio upon arrival. They will then proceed with the installation of a new stone base, carefully grading it to ensure optimal drainage and stability. Once the base is compacted, it will be ready for inspection by the local village or city as required.

We strive to complete the framing as quickly as possible, either on the same day or the following day, in order to facilitate the necessary pre-pour inspections.

It is essential to be aware that after the base and frames have been prepared for Concrete Paving in Antioch, Illinois, parking vehicles on the area will not be feasible.

STEP 2.

INSPECTIONS

Upon completing the base preparation for your Concrete Paving project in Antioch, Illinois, our next step will be to schedule any necessary base inspections.

After passing the inspection, we will work with you to schedule the project pavement installation, which is usually planned between 1-3 days after the base is prepared and ready, weather permitting.

In most villages, there is typically no requirement for someone to be present during the inspection. However, it is essential to comply with the regulation of visibly posting the permit on a front window or door, and keeping the approved plans accessible if they are requested.

Please note that in certain Villages, a base inspection may not be necessary. Rest assured, we will provide guidance and inform you if a base inspection is not required. In such instances, we will expedite the paving process to the earliest available schedule.

STEP 3.

CONCRETE INSTALLATION

Our professional team of concrete installers will efficiently handle the paving process. They will pour the fresh cement, giving you the option to incorporate color into the mixture. The team will ensure an even distribution of the cement, resulting in a leveled surface. If requested, they will use stamping techniques and apply a release layer to create attractive patterns and textures.

As construction is underway, we recommend reaching out to your local police department to secure a street parking permit.

Patience is key when it comes to concrete installation. It is important to refrain from parking vehicles on the concrete surface for a minimum of 5-7 days to allow it to properly set and establish its strength.

WHEN DO I NEED TO REPLACE?

IF YOU NOTICE ANY OF THE FOLLOWING ISSUES:

DEEP PENETRATING CRACKS

EXCESSIVE PITTING (APPEARS AS THOUGH PIECES OF STONE ARE EXPOSED OR MISSING)

EXPOSED RE-BAR OR WIRE MESH

SLABS SETTLED, SLANTED, UNEVEN, OR RAISED

WATER SEEPING INTO THE FOUNDATION OR UNDER THE DRIVEWAY

MAJOR GAPS BETWEEN SLABS AND WHERE CONCRETE USE TO MATCH OTHER SURFACES

DECORATIVE CONCRETE PAVING IN ANTIOCH

THE MOST POPULAR USES FOR RESIDENTIAL CONCRETE

Exposed aggregate concrete

The application of exposed aggregate concrete offers an incredibly attractive and straightforward method for creating a captivating decorative surface.

Through the process of selectively stripping away the surface layer of concrete, like that of a driveway or an interior floor, the inherent beauty of the aggregates is showcased, creating a distinctive visual presentation with varying sizes.

Exposed Aggregate Concrete Applications:

- Garage Floor Coating

- Concrete Steps and Stairs

- Concrete Driveways

- Concrete Patios

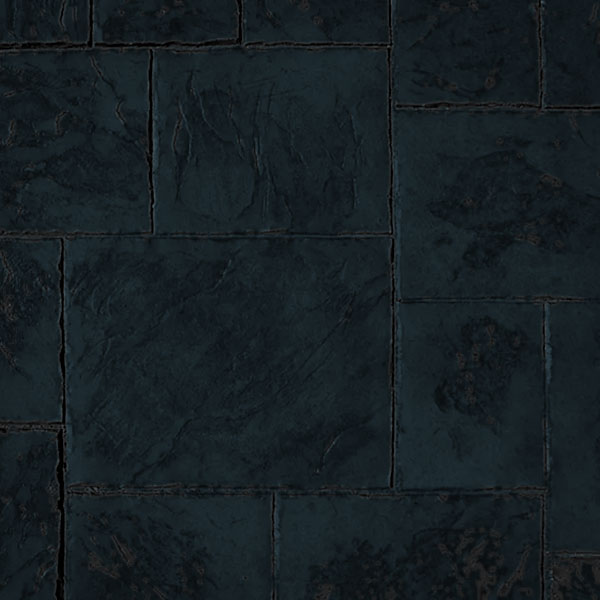

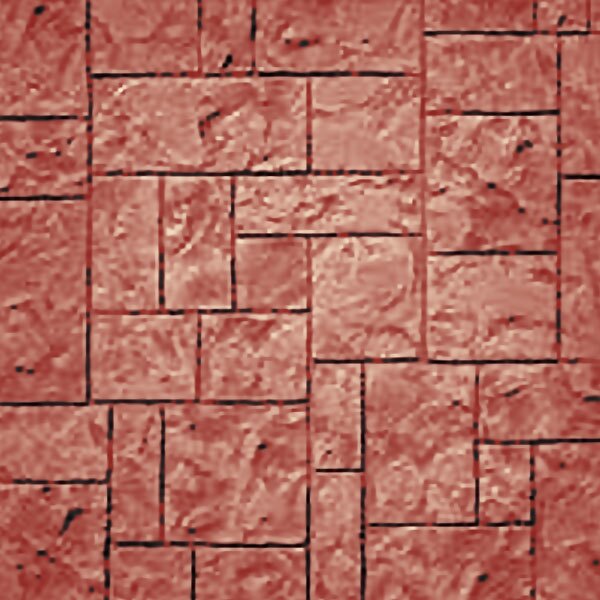

Stamped Concrete

If you desire the look of pavers or natural stone but prefer a maintenance-free option, stamped concrete is an ideal choice. With the ability to mimic different patterns and colors, it is widely used for patios, sidewalks, and driveways.

Stamped concrete stands out as a widely embraced form of decorative concrete, known for its capacity to emulate the aesthetic of higher-priced materials, making it an excellent choice for achieving a sophisticated look.

Through the skillful application of colors and careful stamping, stamped concrete captures the essence of brick or stone tiles, offering an affordable option for creating a similar visual impact.

Stamping concrete is a skilled task that necessitates the involvement of concrete professionals, who possess the knowledge and dexterity to apply the staining and stamping elements to the fresh concrete prior to it hardening. After the concrete attains its optimal plasticity, a careful application of a release layer is performed to accentuate the desired color contrasts and facilitate the seamless maneuvering of the stamping tools, preventing them from sticking to the concrete. Following the stamping process, a curing compound and sealer are meticulously applied to the surface, providing essential protection and extending the lifespan of the concrete.

Though the ideal scenario for stamping concrete is when it is freshly poured and wet, overlays offer an adaptable solution by introducing a layer of 2 inches of fresh concrete. This means that if your current concrete is in good shape, you can effortlessly upgrade your flat driveway or patio with an impressive stamped design that will breathe new life into the area.

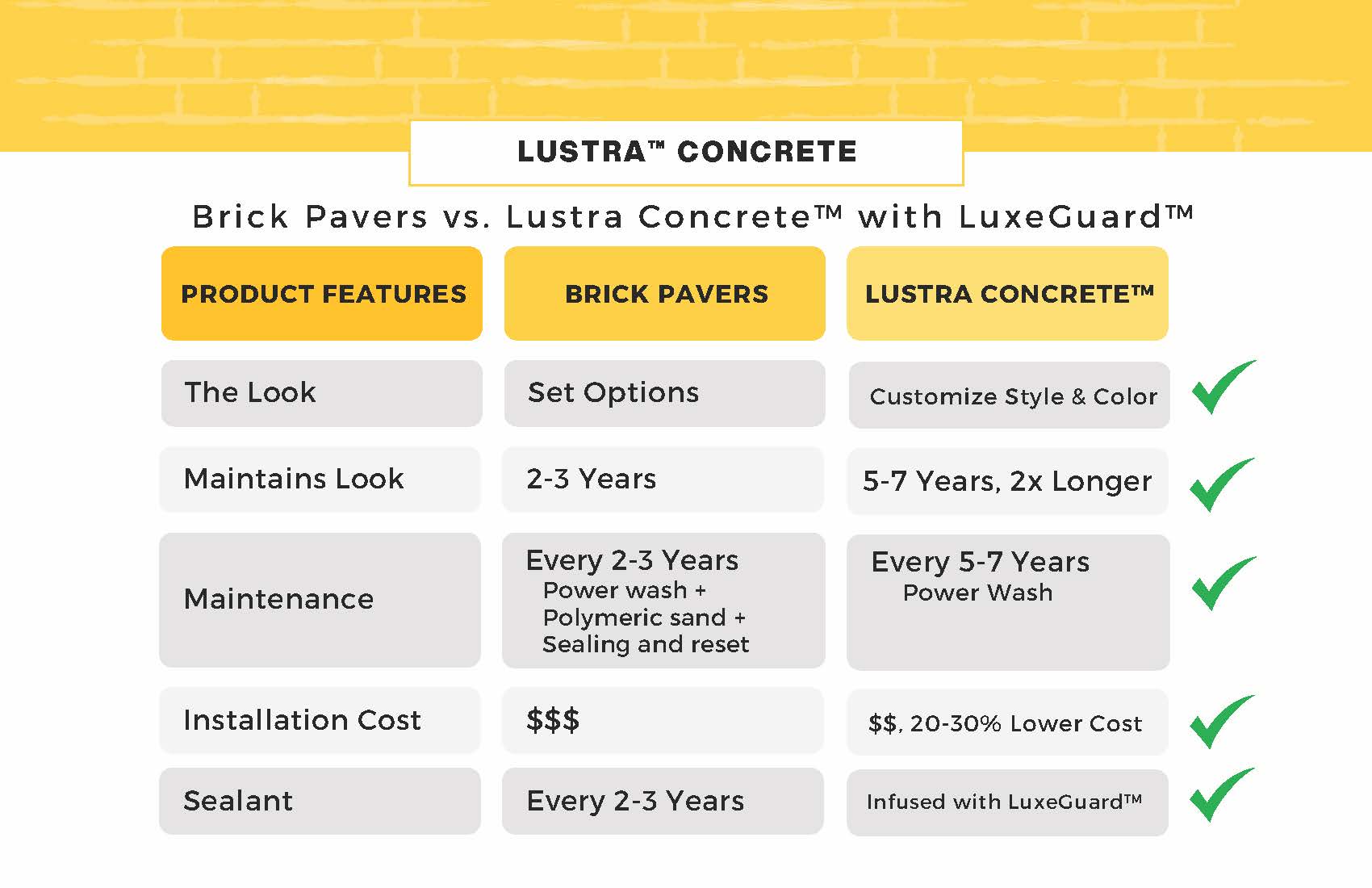

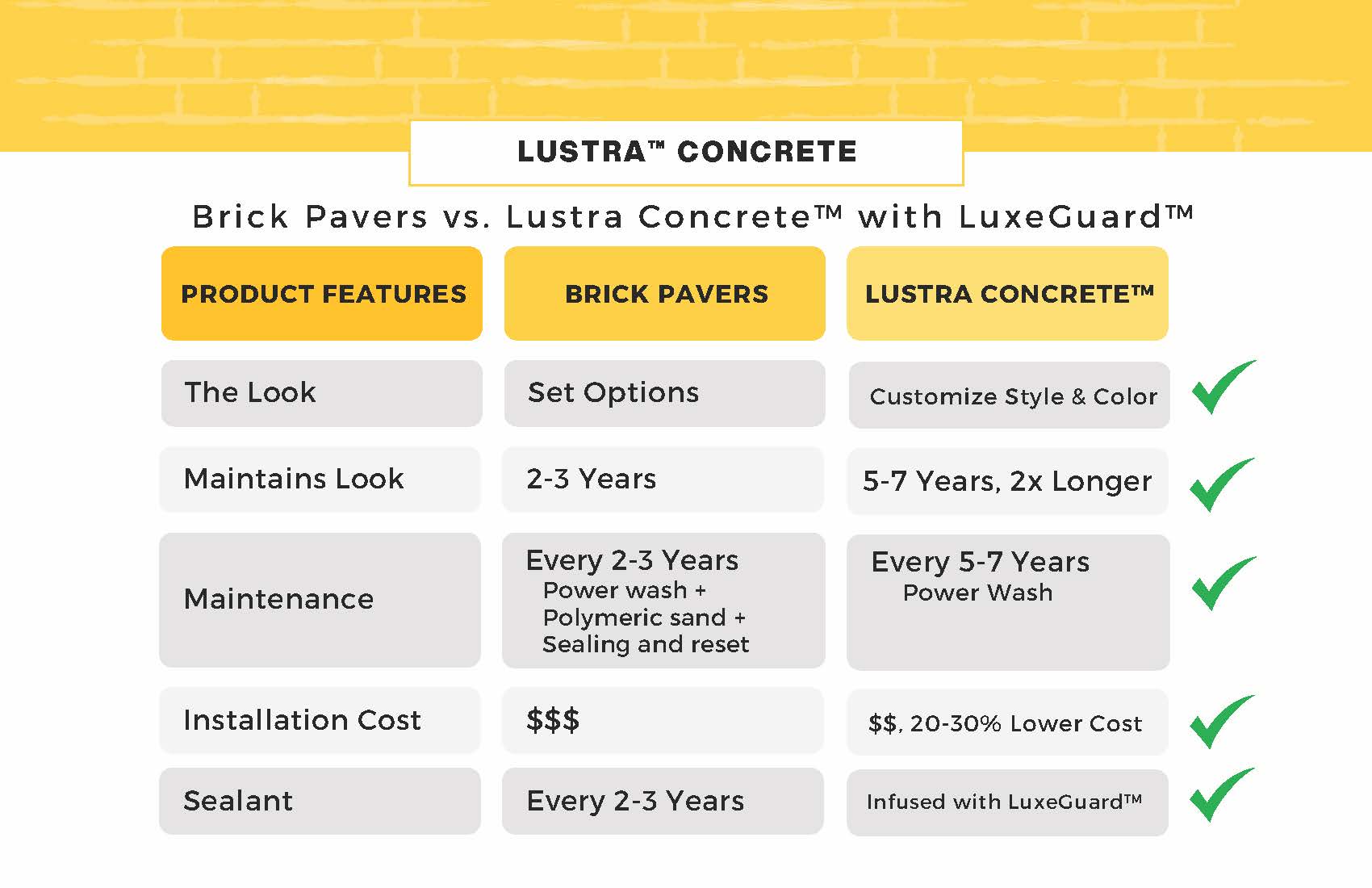

Lustra™ Concrete with LuxeGuard™

Elevate your outdoor spaces with Lustra™ concrete enhanced by the protective power of LuxeGuard™. Designed for patios, sidewalks, and driveways, Lustra™ offers the perfect blend of beauty and durability.

This decorative concrete solution delivers the high-end, sophisticated appearance of premium materials—without the high price tag. Ideal for homeowners and businesses seeking both style and value, Lustra™ is the cost-effective alternative for achieving an upscale look that stands the test of time.

Why Choose Lustra™ Concrete?

- Versatile Applications:Perfect for patios, sidewalks, driveways, and more.

- Sophisticated Appeal: Achieve the look of premium materials at a fraction of the cost.

- Durable Protection:LuxeGuard™ technology provides enhanced longevity and resistance to wear.

Choose Lustra™ with LuxeGuard™ and experience affordable elegance and performance for all your paving needs.

Lustra™ Concrete with LuxeGuard™

Elevate your outdoor spaces with Lustra™ concrete enhanced by the protective power of LuxeGuard™. Designed for patios, sidewalks, and driveways, Lustra™ offers the perfect blend of beauty and durability.

This decorative concrete solution delivers the high-end, sophisticated appearance of premium materials—without the high price tag. Ideal for homeowners and businesses seeking both style and value, Lustra™ is the cost-effective alternative for achieving an upscale look that stands the test of time.

Why Choose Lustra™ Concrete?

- Versatile Applications: Perfect for patios, sidewalks, driveways, and more.

- Sophisticated Appeal: Achieve the look of premium materials at a fraction of the cost.

- Durable Protection: LuxeGuard™ technology provides enhanced longevity and resistance to wear.

Choose Lustra™ with LuxeGuard™ and experience affordable elegance and performance for all your paving needs.

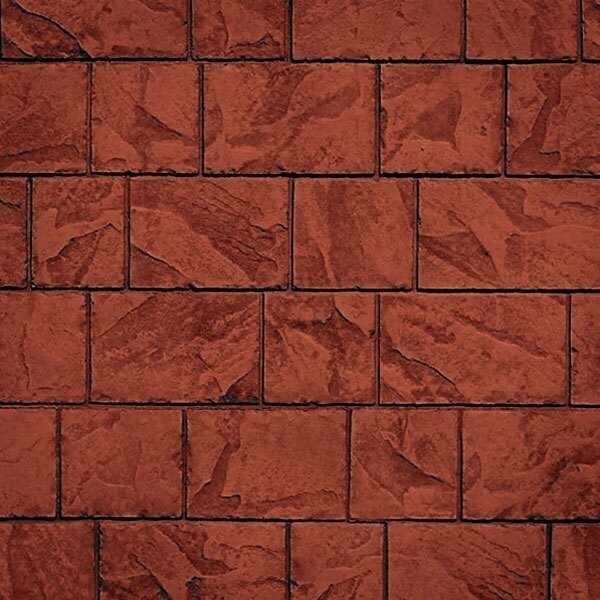

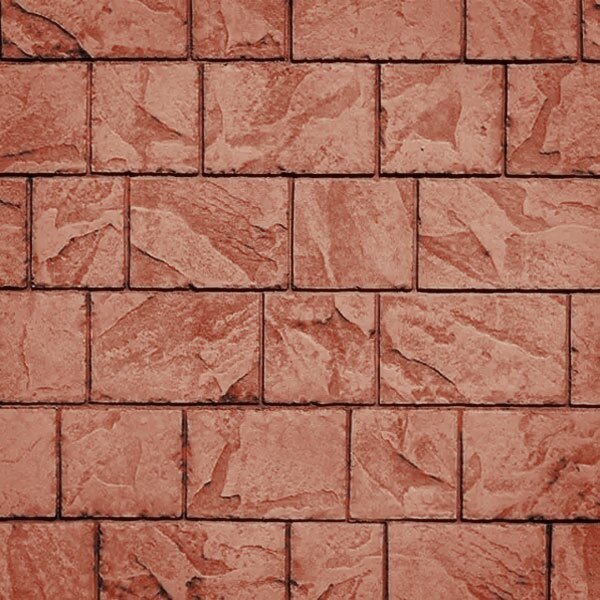

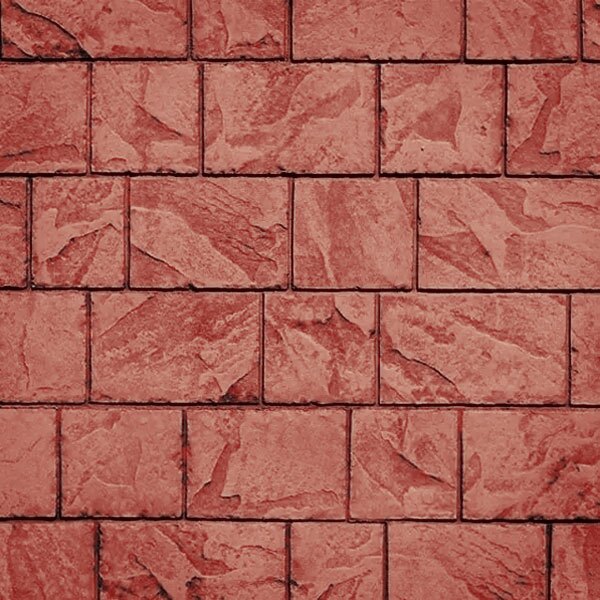

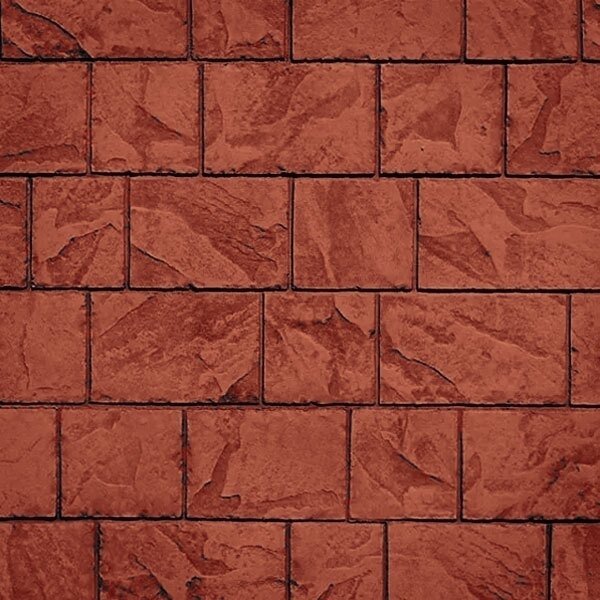

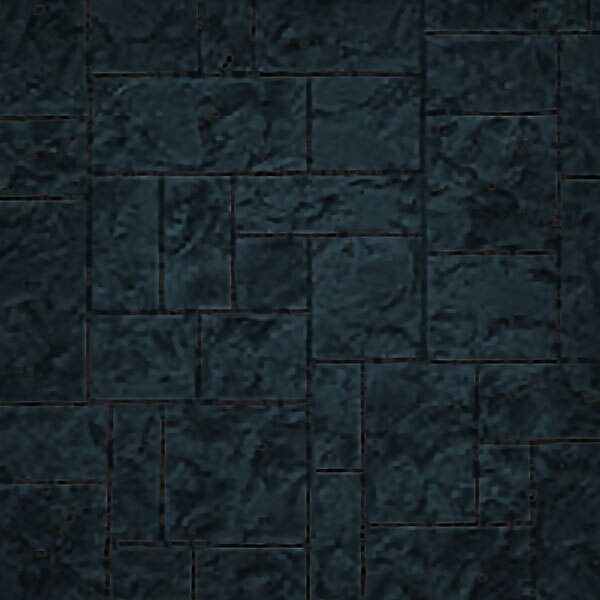

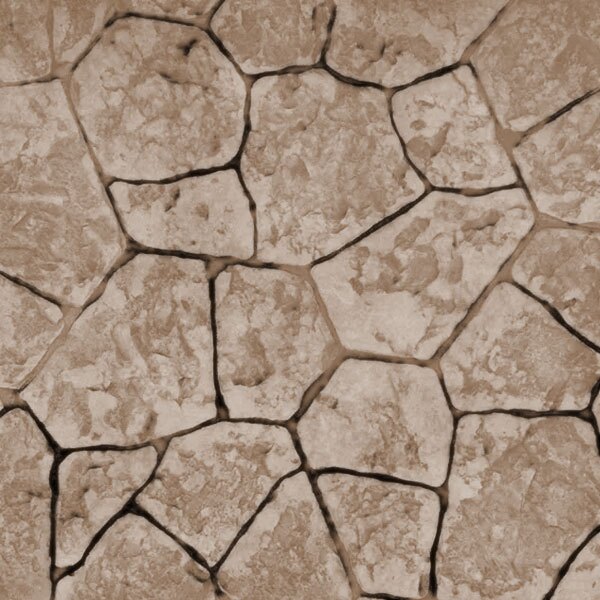

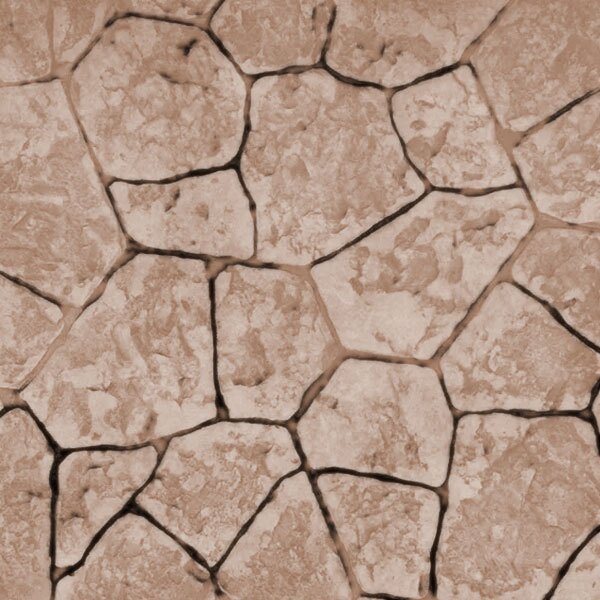

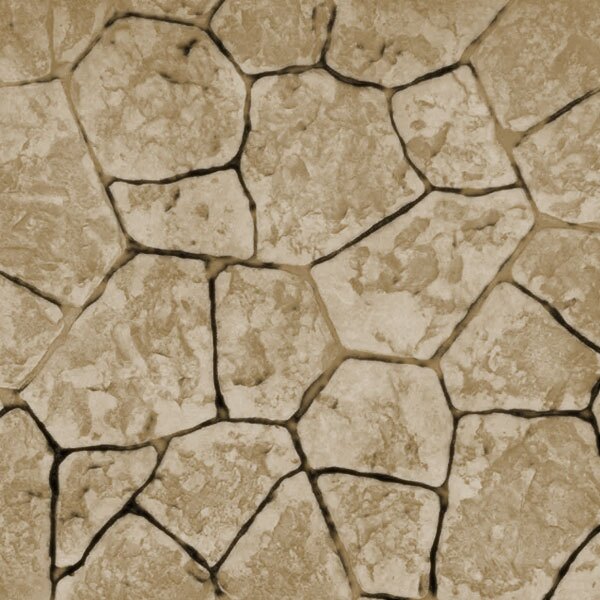

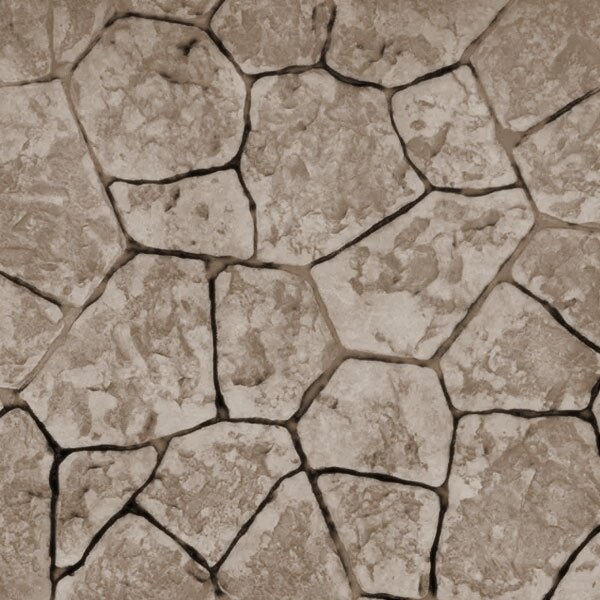

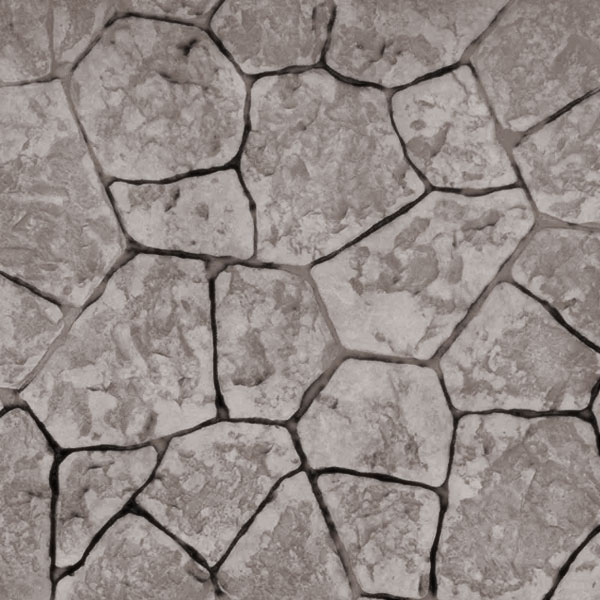

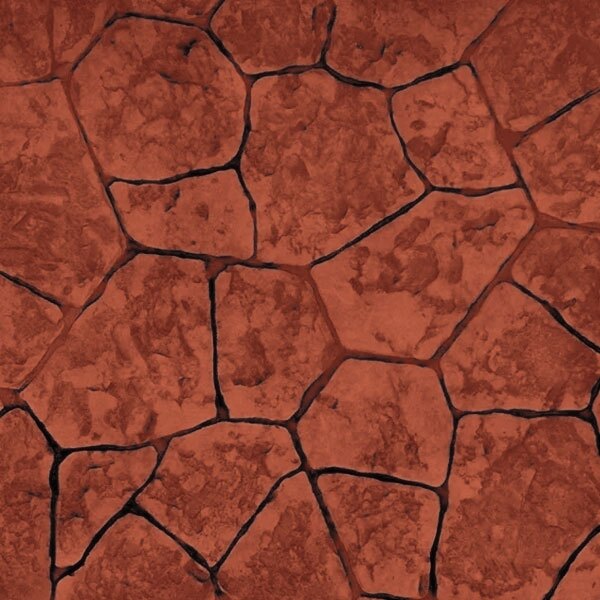

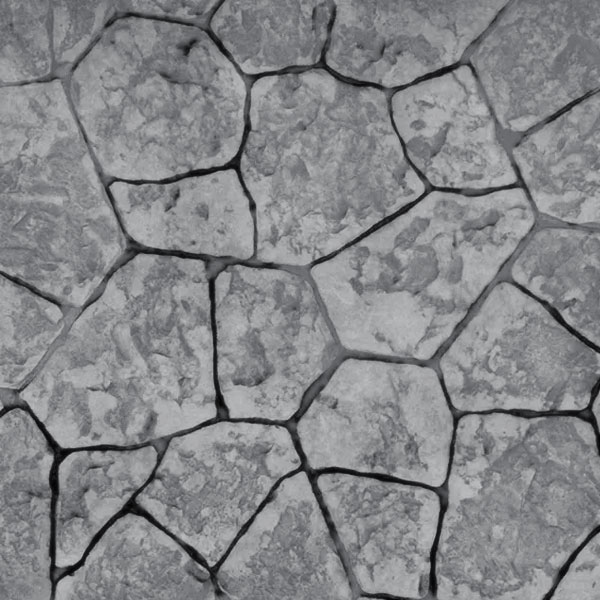

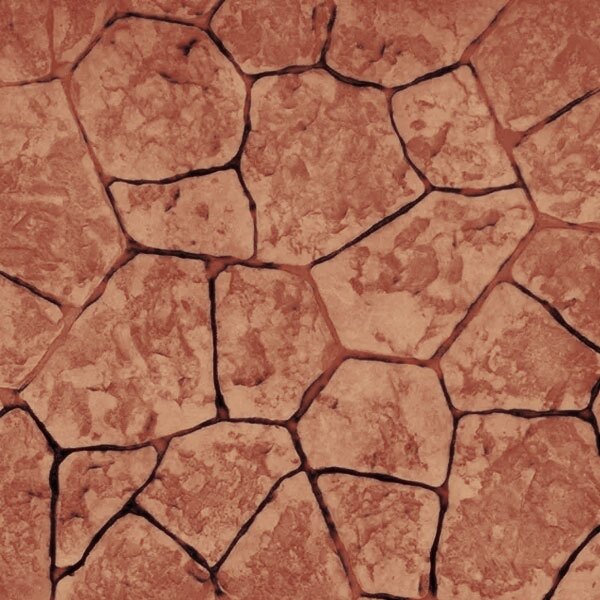

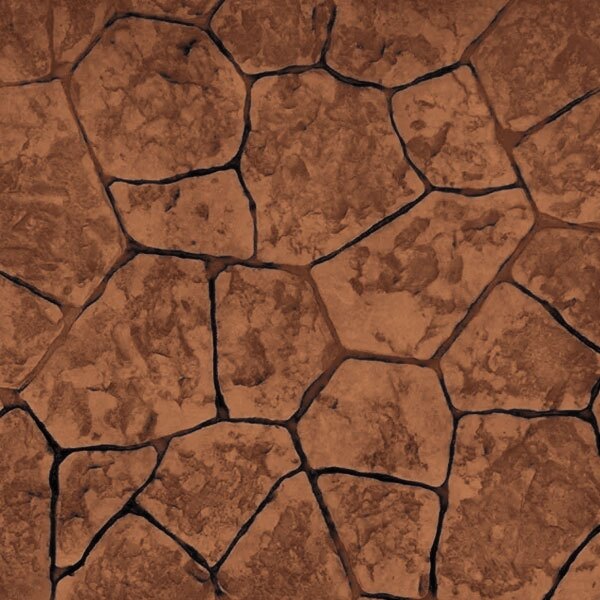

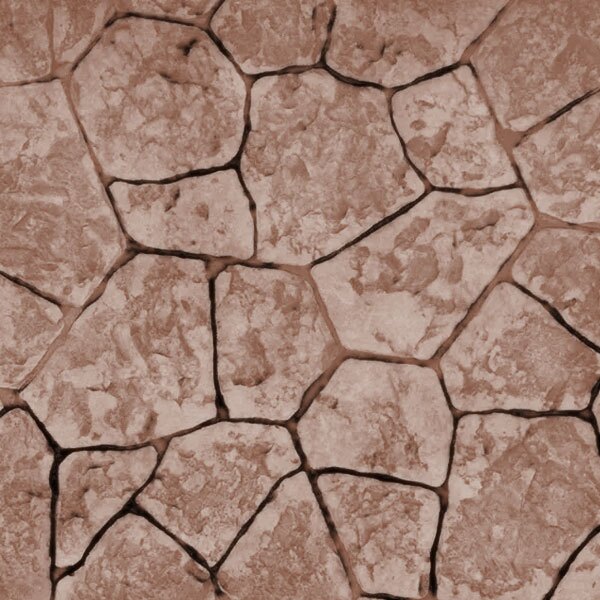

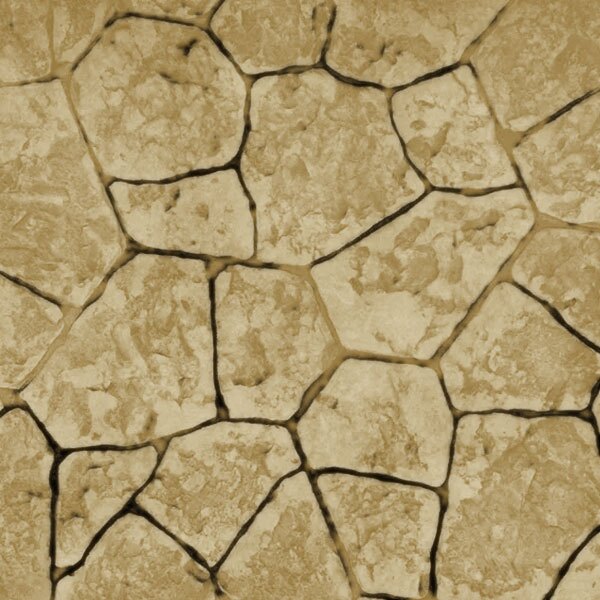

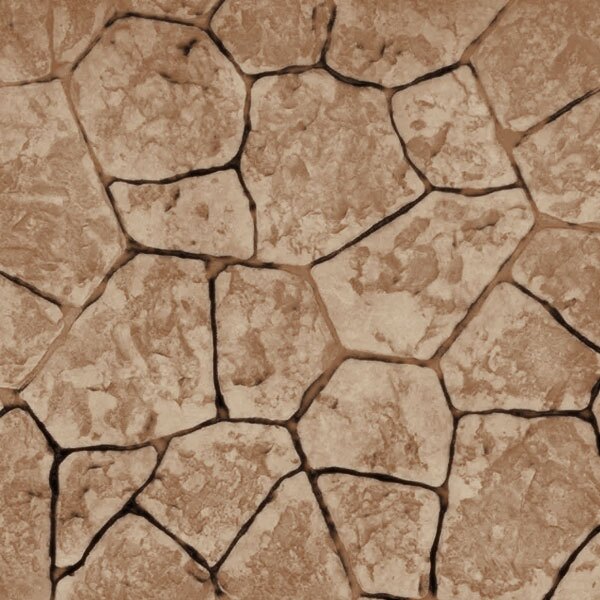

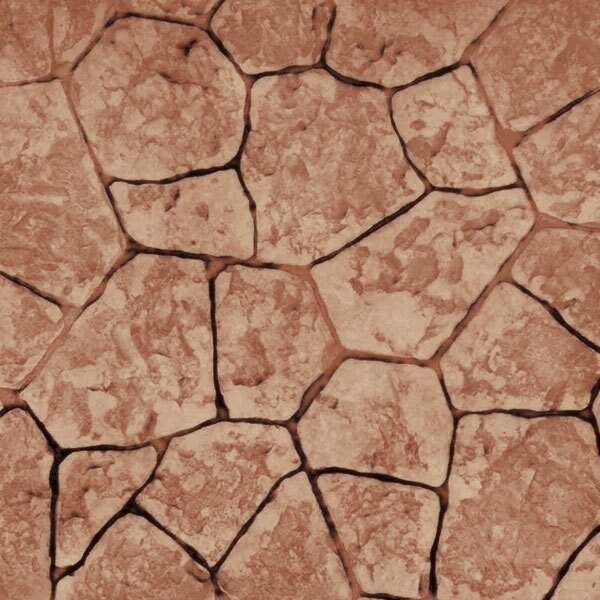

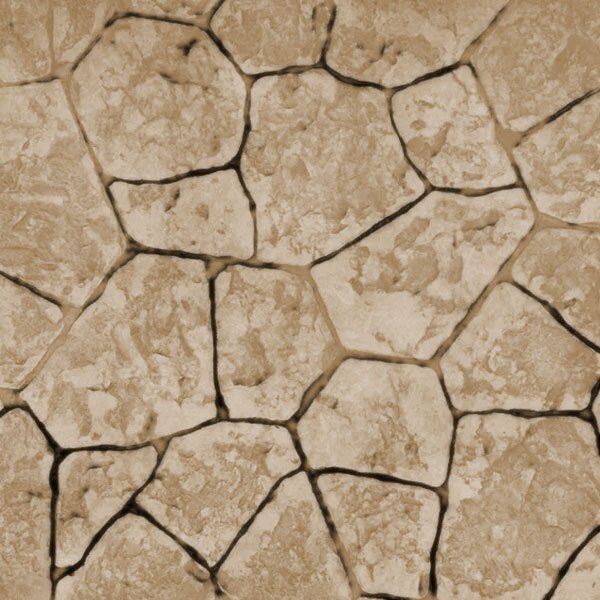

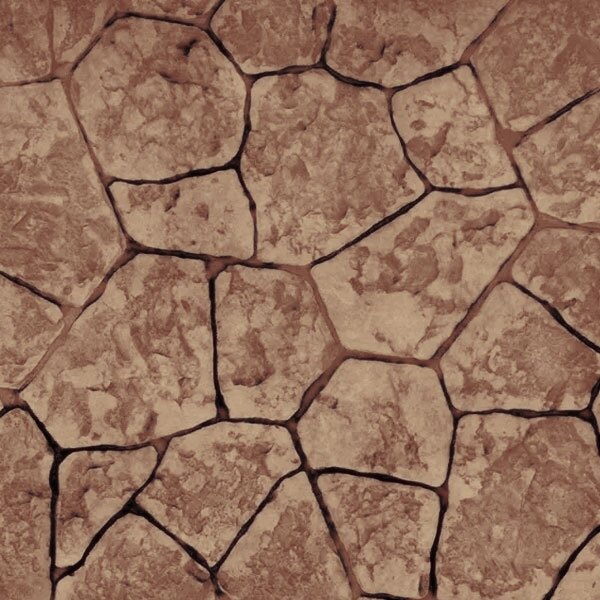

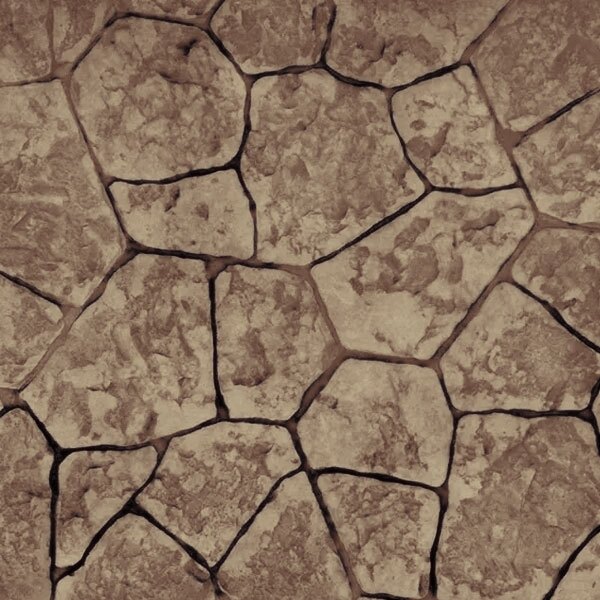

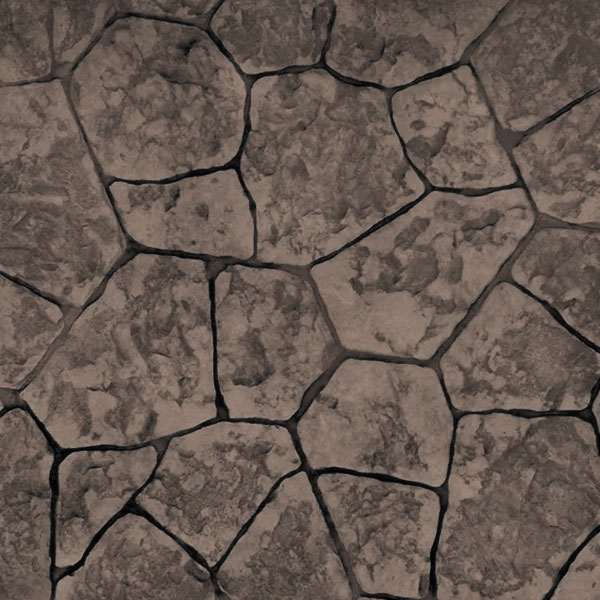

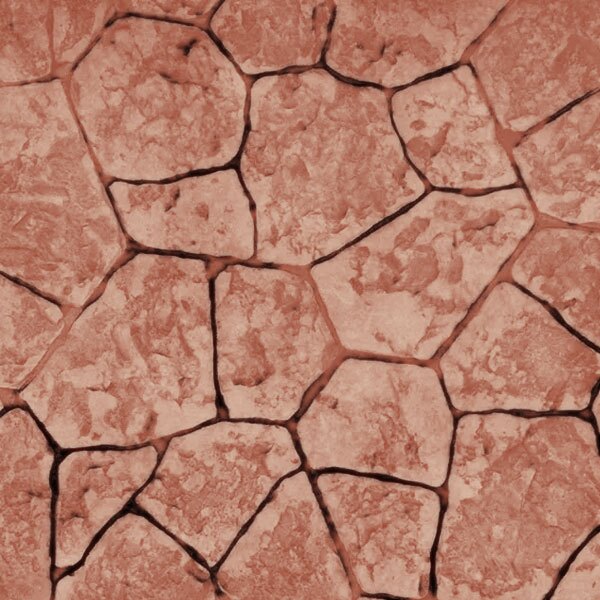

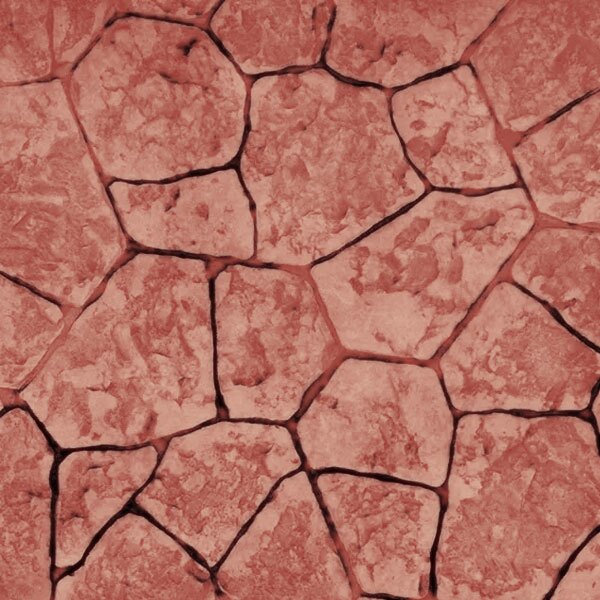

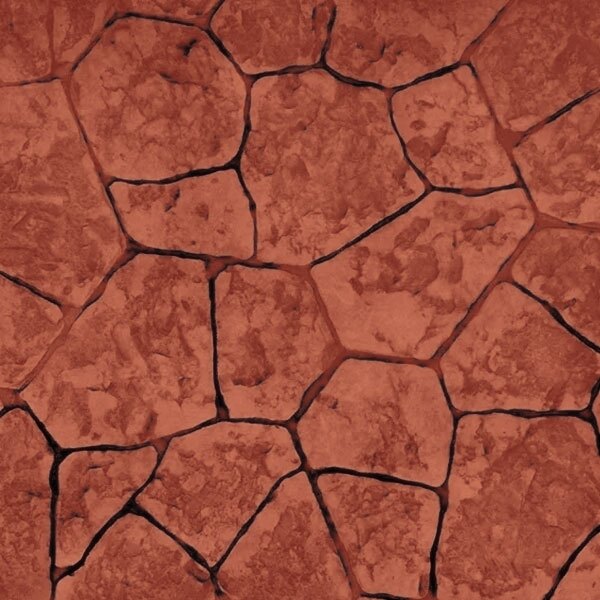

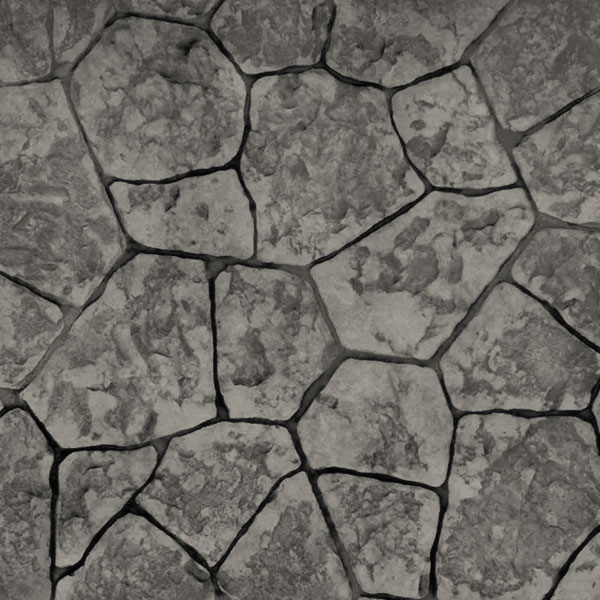

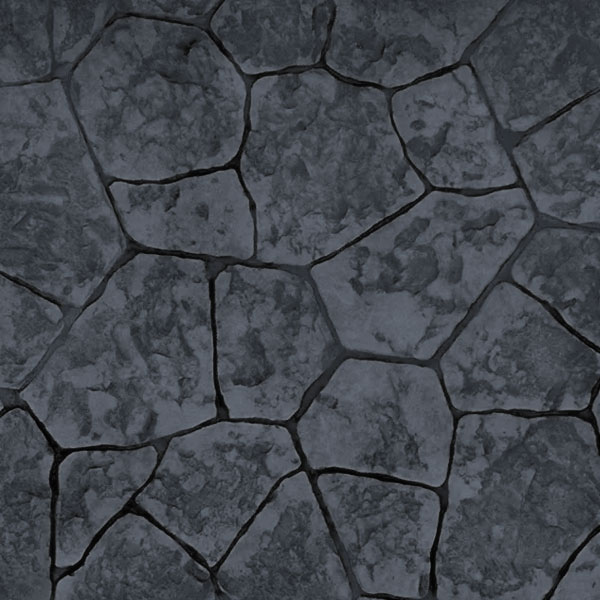

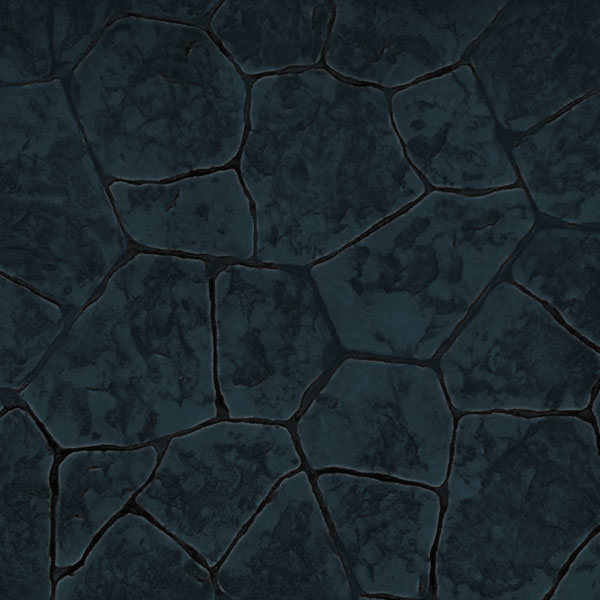

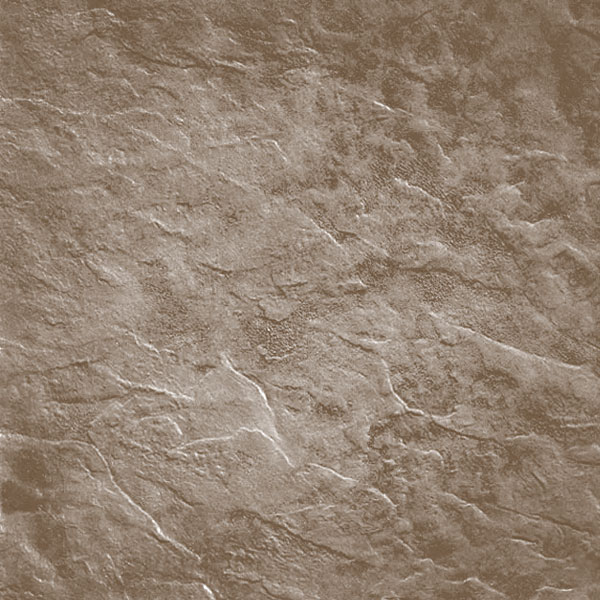

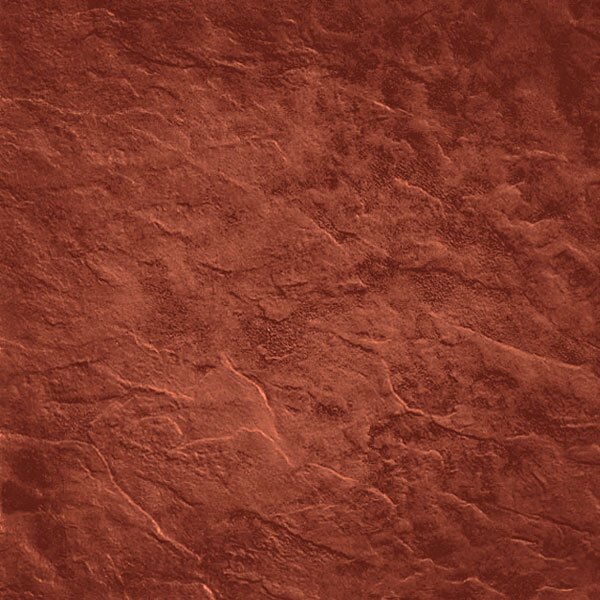

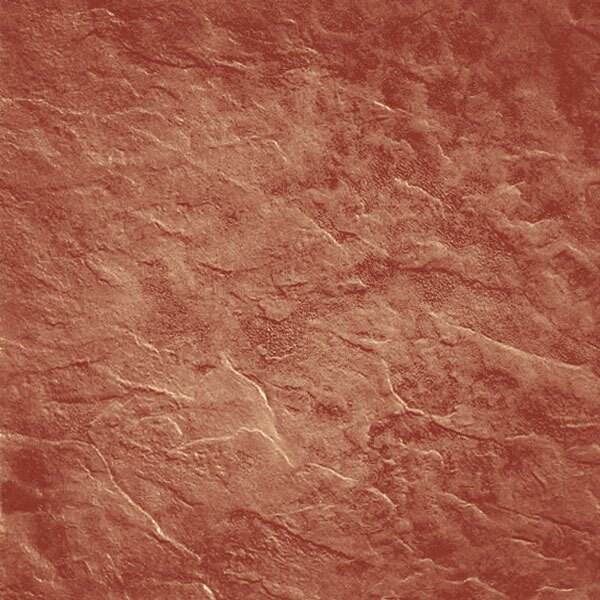

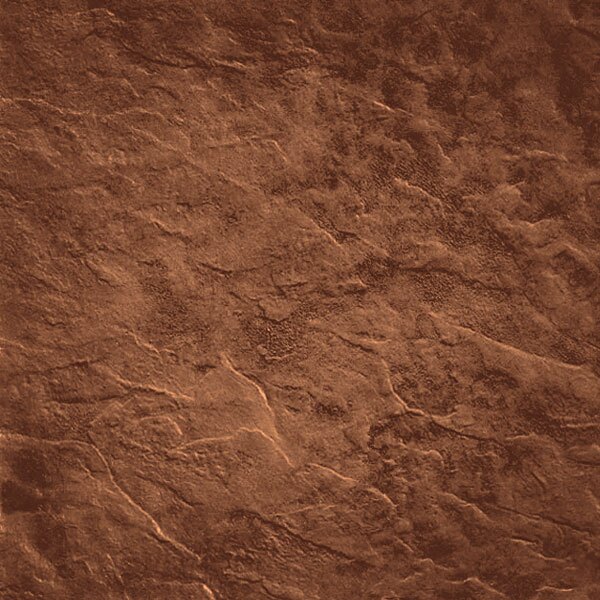

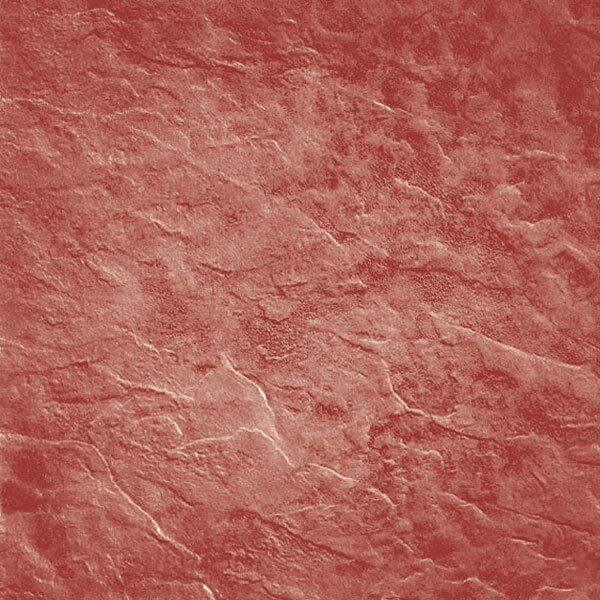

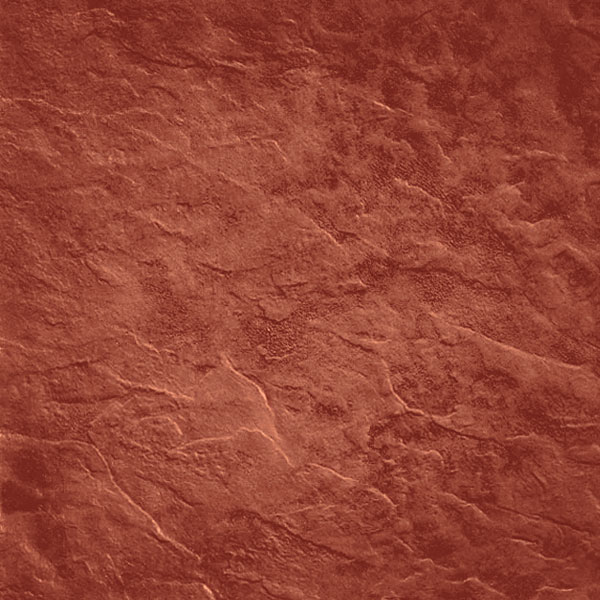

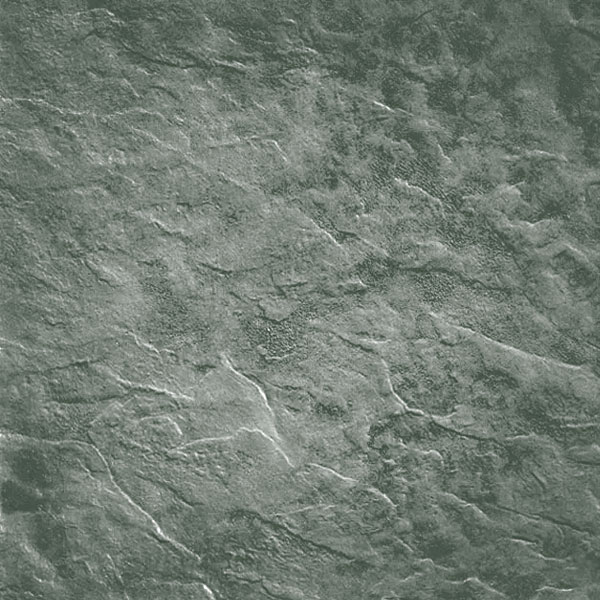

STAMP COLOR SIMULATOR

CUSTOMIZE, VISUALIZE & MAKE A BETTER CHOICE

1. Choose a Pattern

-

VERMONT SLATE

VERMONT SLATE -

ASHLER STONE

ASHLER STONE -

CANYON STONE

CANYON STONE -

FRACTURED SLATE

FRACTURED SLATE -

LONDON SLATE

LONDON SLATE

2. Pick a Color

- Spring Beige

- Summer Beige

- Autumn Beige

- Winter Beige

- Porcelain Gray

- Sorrento Red

- Cool Gray

- Sunbaked Clay

- Brownstone

- Desert Sand

- Limestone

- Sombrero Buff

- Antique Cork

- Mesa Beige

- Adobe Tan

- Coachella Sand

- Westwood Brown

- Tawny Pink

- Coral Red

- Quarry Red

- Shadow Slate

- French Gray

- Charcoal

- Dark Gray

- Spring Beige

- Summer Beige

- Autumn Beige

- Winter Beige

- Porcelain Gray

- Sorrento Red

- Cool Gray

- Sunbaked Clay

- Brownstone

- Desert Sand

- Limestone

- Sombrero Buff

- Antique Cork

- Mesa Beige

- Adobe Tan

- Coachella Sand

- Westwood Brown

- Tawny Pink

- Coral Red

- Quarry Red

- Shadow Slate

- French Gray

- Charcoal

- Dark Gray

- Spring Beige

- Summer Beige

- Autumn Beige

- Winter Beige

- Porcelain Gray

- Sorrento Red

- Cool Gray

- Sunbaked Clay

- Brownstone

- Desert Sand

- Limestone

- Sombrero Buff

- Antique Cork

- Mesa Beige

- Adobe Tan

- Coachella Sand

- Westwood Brown

- Tawny Pink

- Coral Red

- Quarry Red

- Shadow Slate

- French Gray

- Charcoal

- Dark Gray

- Spring Beige

- Summer Beige

- Autumn Beige

- Winter Beige

- Porcelain Gray

- Sorrento Red

- Cool Gray

- Sunbaked Clay

- Brownstone

- Desert Sand

- Limestone

- Sombrero Buff

- Antique Cork

- Mesa Beige

- Adobe Tan

- Coachella Sand

- Westwood Brown

- Tawny Pink

- Coral Red

- Quarry Red

- Shadow Slate

- French Gray

- Charcoal

- Dark Gray

- Spring Beige

- Summer Beige

- Autumn Beige

- Winter Beige

- Porcelain Gray

- Sorrento Red

- Cool Gray

- Sunbaked Clay

- Brownstone

- Desert Sand

- Limestone

- Sombrero Buff

- Antique Cork

- Mesa Beige

- Adobe Tan

- Coachella Sand

- Westwood Brown

- Tawny Pink

- Coral Red

- Quarry Red

- Shadow Slate

- French Gray

- Charcoal

- Dark Gray